Avoid common biogas mistakes for a more productive future

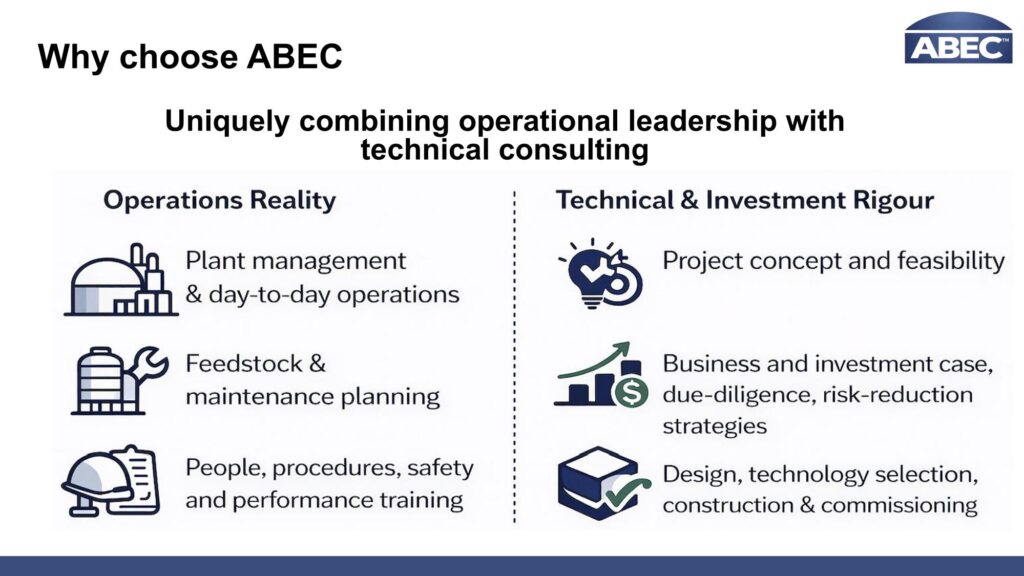

If you’re in the biogas industry, chances are you will have connected with Flávio Ascenco over the past few years. Having cut his teeth in food waste operations, he was soon running AD plants with great success. This gave him the foundations to progress into being the Technical Lead for both ADBA and The World Biogas Association. Now he is the founder of Agile Biogas (ABEC) – offering engineering and technical advisory support across anaerobic digestion, biogas and biomethane projects.

Abbie – How long have you been in the biogas industry?

Flávio – I’ve been in this sector for over a decade now, around 14 years. I started working in operations, on commissioning, optimisation of site, that sort of thing. More recently: strategic, advisory and sector leadership. In short, from being hands on with processes, all the way to shaping national and international industry agendas.

Abbie – What inspired you to take this career path?

Flávio – I guess I came into this career by mistake. I wanted to get into the renewable energy, that’s what I studied. Then I came across the biogas sector and started with operational work and enhancing the performance of a plant. Two things inspired me to do this: the potential of biogas to solve not only energy problems in the real world but also waste challenges. Biogas fixes both. The recurring operational issues on ground level led me to have a different vision and interact with engineers, feedstock suppliers, investors and people who understand what needs to be done to drive performance. Through this I’ve realised the sector doesn’t need more technology, we don’t need more policies, we need execution. That’s where attention is needed at the moment.

Abbie – Do you think that’s been your biggest learning curve?

Flávio – Yes, that, and understanding that the mission needs to be clear. Raise the reliability, build capacity, help the industry, but all with the focus on the operations. Many many plants are built but usually the technical person only comes in during the final stages of the project. They should be there from the start. That’s the main issue. Sites are often built incorrectly, then the plant fails and they bring in the technical people to fix it. If you use technical advisors from the start you will not only save money but you will be able to allocate the right resources into the right places.

Abbie – You did a lot of traveling for work during your time at World Biogas Association, which countries initiatives are you most impressed with?

Flávio – I have a few I’d like to mention. For example, Denmark. Their operational discipline and integration of the biogas with all of the wider energy sector is simple and effective. Denmark is fantastic at moving things forward. Still in Europe, I would also have to say: Italy. I like particularly that they make biogas to help farmers to help the industry. The key reason for this was not only energy security but for waste reduction and helping to promote a circular economy. The UK as well from the perspective of dedication to keeping operational procedures right. Health and safety, environmental procedures etc. If we get out of Europe I’d like to mention India because of their ambition to build rapidly and scale up. They’re very eager to be at the forefront but there’s still a lot of work to do. They already have the technology, some policy implemented but they are failing on execution. Mainly due to the lack of knowledge there. It’s improving so hopefully it will continue. On the other hand, if we travel over to the Americas I would have to say Brazil. I think the innovation that’s happened there, the knowledge and their striving for more is fabulous. I’ve been a few times and they just love biogas there.

Abbie – If you were to ask governments to do one thing, what would it be?

Flávio – I’d ask for two things to be honest. More access to knowledge and a commitment to long term policy frameworks. Give the industry enough time to mature with confidence. So the developers, the operators, the financers will have trust that once something is in place it will run for the duration of the project. A clear example from the UK is the Green Gas Support Scheme. It was put out as a great action but it finishes in 2026, so it then gets extended to 2028. It’s been extension after extension and it holds back progress. If from the start they put it in place until 2030 for example, if would have given enough time for you to think ahead with your project, make the right considerations, conduct the right studies etc. I must say that during the time I was at ADBA, I saw first hand how powerful the engagement with good policy can be. Thankfully, the policy team at ADBA are doing a fantastic job at getting to government with the right messages. Biogas is capable of delivering real climate change.

Abbie – Do you have a funny industry stories you can share with us?

Flávio – Well there’s so many but some of them can not be told to the public. I can think of one though, at a plant that’s quite well established. At the moment everyone talks about AI being the future, which in some respects it is, and I agree with a lot of it. However, I remember I was on site and everyone was saying “oh this plant is great, it’s fully automated, it runs itself, it hardly needs anyone”. I’m thinking ok, I’ve run sites for years and I’ve never seen anything run on its own. You always need good people on site with experience and knowledge. Anyway, within five minutes you see an engineer running around as this big alarm goes off. They say “Oh the CHP tripped, don’t worry guys this happens all the time, we just have to go over there and fix it”. So it just shows, although it can be fully automated, you always have a stressed operator looking after it. This is why training is so important.

Abbie – Is that what made you decide to set up Agile Biogas, was it a lot to do with the training?

Flávio – A bit of everything. The reason ABEC was launched is to get the execution done, the industry does not need any more theory. There’s so many plants around the world being built incorrectly and underperforming because they’re suffering from the start. This is due to fragmented knowledge, inconsistent standards, and lack of practical and operational guidance. People need technical guidance and support to run these sites. At our core our mission becomes very easy. We want to help the industry to deliver high quality, high performance biogas sites. Simply by us providing technical advice, training and operational insights to make a difference.

Abbie – What are the biggest mistakes that biogas plants make?

Flávio – I could give you a list of twenty, forty, sixty different mistakes but the most common are;

- Rushing at the early stages – poor visibility studies, weak concept design and unclear responsibilities

- As I mentioned before, lack of knowledge – People still treat it like other industries like solar or wind, but we are dealing with biology

- Underestimating operations – not enough training and monitoring quality

- Poor handovers – EPCs leave the site and the operators don’t have the right tools to run the plant effectively

Overall, the main point is that most of the long term problems can be tracked back to the decisions made right at the early stages of the project. For example if you need to replace a pump but the design does not allow it.

Abbie – If you could give one piece of advice to project developers what would it be?

Flávio – Invest properly in the early stages. A strong feasibility study, a robust concept design, and an experienced Owner’s Engineer will save years of headaches and millions in lost performance. Bring technology experts such as ABEC from the beginning. We see the end and we know what must be done from the start. Biogas rewards good planning and punishes shortcuts. Build it well, build it once. Developers needed clearer guidance. Agile Biogas is my way of bringing operational excellence, engineering discipline, and practical experience together to help the sector mature. Project developers must engage with technical experts a early stages.

If you have any questions about this article or using ferrous chloride at your plant, please feel free to contact us.